Commings engine PT spray hole drop oil phenomenon analysis

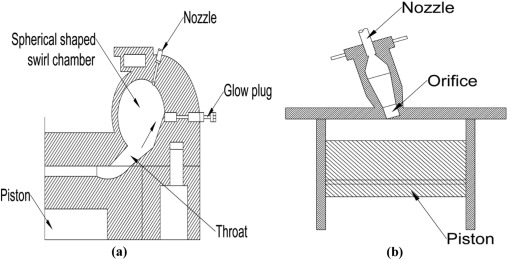

In the early 80s, the Shandong bulldozer main plant the D85A-18 crawler dozer which introduced from the Japanese small pine manufacture, used the Commings engine. Commings engine PT fuel delivery system's characteristic:The fuel feed is decided in the PT pump supplies spray hole fuel pressure and opens the spray hole gauged orifice the absolute time.The PT pump is the low press pump, the discharge pressure generally in 0.8~1.2MPa, the spray hole spraying fuel oil pressure in 68~136MPa.The PT fuel system (Figure 1), fuel oil tank's position is higher than the PT pump and the PT spray hole.

Figure 1 PT fuel system's composition

1 PT spray hole structure

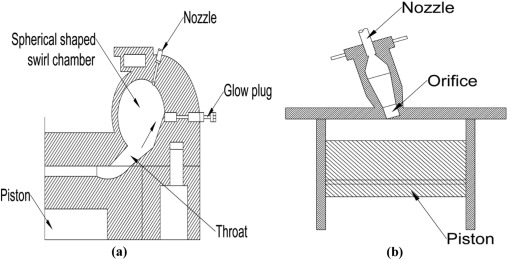

The PT spray hole is the machinery opens the type spray hole. In the spray hole mouth the uniform distribution has 7 or 8 nozzles, the nozzle diameter approximately 0.2mm, the nozzle spool thread with is vertical has 17 the angle in the spray hole plunger 17 spool thread's planes, its structure see Figure 2.

Figure 2 PT spray hole structure

2 PT spray hole drop oil phenomenon analysis

The PT fuel system pertinent data indicated that the PT spray hole's fuel oil measurement stage is moves from the piston after the intake stroke top dead center when the crank corner 44 position starts, moves upwardly until the piston before the compression stroke top dead center 28 the crank corner position, in the spray hole measurement stage, the fuel oil enters the oil duct and the spray hole pressure chamber is interlinked, again 7 or 8 nozzles and the air cylinder is interlinked through the pressure chamber mouth. The spray hole has provided the possibility in the structure for the drop oil phenomenon. the table 1 (take 6 cylinder engines as example, work order is 153624) draws the oblique line part for each cylinder PT spray hole fuel oil measurement stage crank corner position. May see crank's any position from the table to correspond has 2 or 3 cylinder's stage PT spray holes is at the fuel oil measurement stage.

Table 1 crank position and spray hole fuel oil measurement stage position correspondence table

May see from the spray hole work process, when the engine stops, besides has 2 or 3 cylinder's PT spray holes is at the fuel oil measurement stage, other PT stage spray hole may the oil discharge, namely the spray hole enter, the output port to be interlinked. Because the PT fuel system uses sets at the fuel tank high, (fuel tank position is higher than the PT pump and the PT spray hole), therefore, once the PT fuel system's cone-way valve 2 closure are lax, will cause in fuel tank's fuel oil through the cone-way valve, the oil discharge oil duct, will pass through again besides is at the measurement stage other PT spray hole to enter the oil oil duct, finally through will be at the fuel oil measurement stage the spray hole to drip into the air cylinder, this has formed the PT spray hole drop oil process, will burn the oil dripping oil oil duct: Fuel oil tank--Cone-way valve--Spray hole oil discharge oil duct--Blow, oil discharge stage spray hole--The spray hole enters the oil oil duct--Measurement stage spray hole--Air cylinder.

3 preventive measures

We had bumped into the breakdown which D85A-18 the bulldozer Commings engine difficulty with starts. Is normal after the inspection engine electric circuit, the oil duct also has the oil, when the starting may see from the cooling fan leaf blade, the crank can transfer the angle is very small, and the reverse moment of force is very big (lets loose button instantaneous). We concluded that the engine has 2 or in 3 cylinders has the fuel oil which infiltrates from the PT spray hole drop, we adopt the reverse extension crank two, then starts successfully, but spouts many fuel oils from the exhaust pipe, had proven our judgment is correct.

Installs a fuel tap when the fuel oil tank, the engine off the fuel tank following fuel tap closure, ceases the drop to infiltrate the fuel oil the source. Hereafter has not broken down this kind of again.